Oil Tanks

All Tanks have Sloped Bottoms for easy pouring & cleaning!

Benefits:

- Prevent Burnt Oils: Double liquid jacketed tanks won’t burn your oils and preserve the quality your customer deserves!

- Sloped Bottoms: Sloped bottoms to ease cleaning and prevent wasting unused oils at the bottom of the tank.

- Easy Pouring: All tanks come with ball valves for easy dispensing. We also sell Heated Ball Valves if your product is prone to quick hardening, like wax.

- Decrease Labor: Our tanks are perfect for masterbatching. Combine your material once a week and use until it’s gone!

- Increase Production: You can produce a lot of soap or candles efficiently.

- Save Time & Money: Less labor, less cost per bar – Equals more profit!

- Built to Last: All stainless steel construction.

- Versatile: Use for Oils, Candle wax, M&P, Honey, and more

- Easy to use and maintain: Sloped bottom for easy cleaning. Keep your jacket full of water, and your tank is good to go!

- No pumps needed: Tanks are designed for easy dispensing into molds, pails, or other containers.

Description:

- Double jacketed tanks suited for all of your heating needs.

- Sloped bottoms on most sizes help prevent waste and improve efficiency.

- Indirect heat and regulated temperature ensures no risk of burning your material.

- Extremely easy to setup, clean, use, and maintain.

- Versatile for use with any product that requires even, controlled heat.

- Large sizes available to masterbatch your product, saving you time and money.

- Best used in conjunction with our Pot Tippers for optimum efficiency when making Cold Process soap.

- All fittings (inner and outer jackets, lid) are 304 Stainless Steel.

- Inlet and Outlet fittings to quickly cool your product for dispensing.

- See our Water Jacket Faucet.

- Our tanks are used across multiple industries. Have a question about your particular application? Contact us.

Included:

- Ball Valve

- Heating Unit

- Tank Lid with Handle

- Oil Heater

Sold Separately:

Oil Heaterboxes & Elements

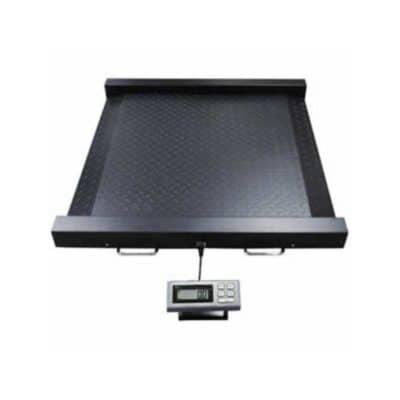

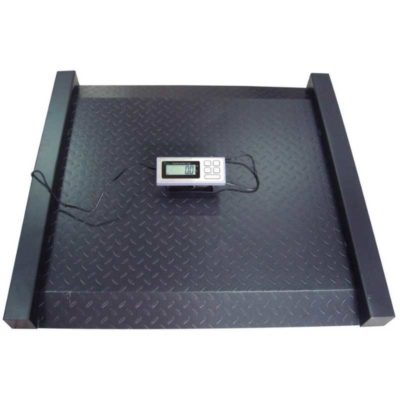

OH Scales

OH Stands

OH Accessories

Tank Systems:

Below are a few examples of custom melting tank designs. Contact us for a quote on your Custom Oil Tank System.

Industries Served:

Cosmetic

Are you making soap, lotion, shampoo, conditioner, body butter, or any other handcrafted body care product? If it needs to be melted, our Oil Melting Tanks are the perfect solution. From 6 – 125 Gallons, we have a size fit for your production. Wondering if our Oil Heaters are a fit for your product? Contact us!

Honey

Our Oil Wax Melters are perfect to use as honey tanks for melting honey. The water jacket aids in maintaining a consistent temperature, which is vital for steady viscosity and uniform filling. The water jacket also brings the honey to temperature over time, instead of heating rapidly over direct heat, reducing the amount of nutrients and benefits lost from the honey.

Candles & Wax Products

Tired of using a single pitcher that only heats up 2-3 candles worth of wax at a time? Our Industrial Wax Melting Tanks have the capacity to melt hundreds of candles worth of wax at a time. The water jacket produces indirect heat, reducing the risk of burning or scorching your wax. Pair with our Heated Ball Valve Assembly to directly pour from the tank.

Auto Industry – Candle Making- Cheese Industry – Cosmetic Industry – Dairy Industry (pasteurizing) – Essential Oil Production – Honey Industry- Industrial Cleaning – Lotion Manufacturing – Food Industry – Soap Making – Testing Labs – Textile Industry – University Labs

Tank Options & Specifications:

Tank Size Capacity & Dimensions

| 6 Gal | 13 Gal | 20 Gal | 45 Gal | 60 Gal | 85 Gal | 125 Gal | ||

| Capacity | Liters | 22.7 L | 49.2 L | 75.7 L | 170.3 L | 227.1 L | 321.7 L | 473.1 L |

| Pounds | 48 lbs | 100 lbs | 160 lbs | 360 lbs | 480 lbs | 680 lbs | 1000 lbs | |

| Kilogram | 21.8 kg | 45.4 kg | 72.6 kg | 163 kg | 218 kg | 308 kg | 454 kg | |

| Water Jacket Volume | Gallons | 4.6 gal | 7.5 gal | 9.7 gal | 16.3 gal | 19.5 gal | 24.1 gal | 30.5 gal |

| Liters | 17.3 L | 28.3 L | 36.7 L | 61.7 L | 73.8 L | 91.2 L | 115.5 L | |

| Dimensions (Height x Diameter) | Inside (in) | 15.0" x 11.1" | 17.1" x 15.1" | 20.0" x 17.2" | 25.1" x 23.0" | 27.6" x 25.2" | 33.0" x 27.5" | 39.7" x 30.4" |

| Inside (cm) | 38.0 x 28.1 cm | 43.4 x 38.4 cm | 51.0 x 43.8 cm | 64.0 x 58.4 cm | 70.1 x 64.1 cm | 84.0 x 70.0 cm | 100.8 x 77.2 cm | |

| Outside (in) | 18.2" x 13.1" | 20.4" x 17.1" | 23.4" x 19.2" | 28.7" x 25.0" | 31.2" x 27.2" | 36.7" x 29.5" | 43.4" x 32.4" | |

| Outside (cm) | 46.2 x 33.2 cm | 52.0 x 43.5 cm | 60.0 x 49.0 cm | 73.0 x 63.5 cm | 79.2 x 69.2 cm | 93.2 x 75.0 cm | 110.3 x 190.3 cm | |

| Electric | # of Heating Elements | 1 | 1 | 1 | 1 | 1 | 2 | 2 |

| Standard Power Draw | 12.5 amps | 12.5 amps | 12.5 amps | 14 amps | 21 amps | 21 amps / ea | 21 amps / ea | |

| Shipping | Shipping Options | UPS | UPS | UPS | Freight | Freight | Freight | Freight |

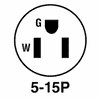

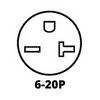

Heater Box Plug Type & Amps

| 120V / 1500W | 220V / 3000W | 220V / 4500W | |

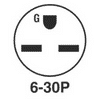

| Plug Type | 5-15P Standard | Nema 6/20p | Nema 6/30p |

| Amperage | 12.5 amps | 14 amps | 21 amps / ea |

| Diagram |

|

|

|

Liquid Jacket (Indirect Heat) vs. Direct Heat Tanks:

Indirect

- Jacketed tanks are used to indirectly heat oils – which prevents the oils from burning/oxidizing in turn.

- Liquid jacket tanks hold a liquid (usually water or propylene glycol) in the outer jacket

- A heating element near the bottom of the tank heats the liquid, which then heats the material in the inner jacket of the tank.

- The liquid disperses to heat the material evenly and prevents hot spots/scalding/burning/oxidation.

- For a detailed scientific review of the effects of oxidation on common oils, please see this review article.

- Jacketed tanks act as a double boiler, similar to a bain-marie in cooking. It is the same principle used when melting chocolate, or baking cheesecake.

- How-to books and online formulas generally require a double boiler for balms, liquid soaps, and lotions.

- A double boiler (jacketed tank) is a good start for beginners to make small batches, and it helps eliminate the possibility of overheating or burning your oils.

- When you scale up production, you want to keep direct heat from your oils while making larger batches – this is the exact reason we designed our tanks.

Direct

- Any tank without a liquid jacket is a “direct heat” tank.

- These tanks can still have jackets, but the heating mechanism is different.

- Direct heat tanks have heating coils between the inner and outer jackets. These coils heat your oil.

- Shouldn’t be used while heating most oils because hot spots in the tanks will oxidize the oils.

- Different oils have different oxidative stability and will react differently to direct heat. However, regardless of the type of oil, applying direct heat will degrade and oxidize the oils.

- Try melting chocolate by melting it with a frying pan, and you will see this principle in action.

- Direct heat tanks can heat up slightly faster (25%) but are less energy efficient.

- Slightly faster can be helpful for material with high oxidative stability, such as candle wax, but is an issue with other oils. The oils heat faster because they are directly in the tank, but this burns material with lower oxidative stability.

- Direct heat tanks have a much higher incidence of fire hazards. Coils and band heaters can burn out, which can result in sparks.

If it does not have a “Liquid Jacket,” it is a “Direct Heat” Tank. If you are making any quality handcrafted product, do not use a Direct Heat Tank.

General Usage Tips:

- Insulate Well: Insulate your wax melting tank with our tank jackets. For maximum efficiency and high-temperature heating, use Propylene Glycol in place of water. More on this below!

- Use a Tank Scale: Keeping your soap tank on a scale full-time allows you to measure the material that is going in and going out at all times.

- Use a Timer: This will eliminate standing around waiting for your material to heat up – timers make sure it is ready when you want it ready. We sell easy-to-install timers on our website.

- Masterbatch Oils: Masterbatching is one of the most efficient uses for our tanks.

- Fill the wax melter up with the correct ratio of base oils. When your material gets low, add more oils based on your ratio.

- You can do this for one day or for a week.

- Use the SoapMaker software if you need help with your formulation.

- Easy Bottling: You can attach our Easy Fill Bottler directly to the tank with our kit.

- We suggest that the tank bottom be level with the bottom of the Hopper.

- A straightforward way to raise and lower the tank is to use a lift. The lift allows you to lower the tank to fill and mix, then raise it to dispense.

Download a PDF here.

Heating to High Temperatures:

When heating above 170°F, we recommend:

- Propylene Glycol:

- PPG allows you to get above the boiling point in the outer jacket, making it much easier to transfer heat to the inner at higher temperatures.

- PPG is safer and more efficient than boiling water, which can cause steam, dripping, condensation, etc.

- It retains heat longer and is more energy efficiently

- If you’re using propylene glycol, make sure it has a corrosion inhibitor. The inhibitor keeps the solution from damaging the element.

- Use a 30-40% solution, 3 parts PPG to 7 parts water.

- High Wattage Element:

- The higher the element wattage and voltage, the easier it is to get to high temperatures

- Tank Insulation:

- Use two of our tank insulation jackets, layered upon each other.

- Place tank on 1″ (25mm) or thicker Styrofoam pad, with a piece of plywood, Masonite, or OSB between the tank and foam.

- Keep Lid Closed:

- Don’t open the lid more than you need to. Constantly checking oil temperatures will let heat out.

Heating Time

Many factors come into play when determining your heating time, such as:

- Material Temperature

- Desired Temperature

- Tank Insulation

- Amount of Material

- State of Material (Liquid, Chunks)

- Melting Point of Material

- Ambient Temperature of Environment

The larger the chunks, the slower the material will heat. The more contact you have to the tank surface, the faster the transfer of heat.

Tip: To turn blocks of material into chunks, take a small wire and wrap it around two short 3/4-1″ (19-25mm) dowels or sticks. Tape so the wire does not poke the fingers. Pull this through the block to cut it up into chunks. It is fast and saves heating energy.

Below are approximate temperature change calculations – Both assume 70° ambient air temperature and that you are heating a full tank.

15 Gallon Oil Heater (120V/1500W)

| Temp Change (F°) | Time (Hours) |

| 10° | 0.24 |

| 20° | 0.48 |

| 30° | 0.72 |

| 40° | 0.96 |

| 50° | 1.20 |

| 60° | 1.44 |

| 70° | 1.68 |

| 80° | 1.92 |

| 90° | 2.16 |

| 100° | 2.40 |

35 Gallon Oil Heater (120V/1500W)

| Temp Change (F°) | Time (Hours) |

| 10° | 1.12 |

| 20° | 2.25 |

| 30° | 2.37 |

| 40° | 4.49 |

| 50° | 5.61 |

| 60° | 6.73 |

| 70° | 7.85 |

| 80° | 8.97 |

| 90° | 10.09 |

| 100° | 11.21 |

35 Gallon Oil Heater (220V/3000W)

| Temp Change (F°) | Time (Hours) |

| 10° | 0.55 |

| 20° | 1.11 |

| 30° | 1.66 |

| 40° | 2.21 |

| 50° | 2.76 |

| 60° | 3.31 |

| 70° | 3.86 |

| 80° | 4.41 |

| 90° | 4.96 |

| 100° | 5.51 |