Industry Use:

Bar Soap

Saponification continues for several weeks as Cold Process soap cures. Proper, even curing is a crucial step in producing the hard, lather-rich, long-lasting quality soaps that your customers desire.

Bath Bombs

Tired of taking up valuable production space with rows of drying bath bombs? Our drying trays are a stackable, space-saving solution that provides a curing space for hundreds of bath bombs, while only 16″ x 32″ of floor space.

Candy + Gummies + Hemp

Our drying racks are perfect for curing gummies. The exclusive vented design allows for maximum surface-to-air exposure. No need to flip or rotate the gummies for even drying.

Benefits:

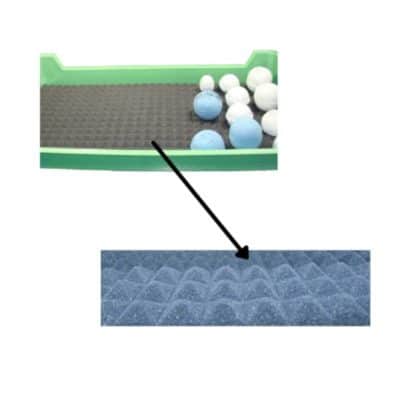

- Speed up Soap Curing Time: Exclusive slot vent design can cut drying time up to 25% or more!

- Ease of Use: Ergonomically designed for easy handling and reach capability.

- Fully Stackable Drying Racks: No need for expensive, space-consuming drying racks.

- Food Grade Drying Trays: Made of Food Grade polyethylene.

- Durable: Broad temperature tolerance and exceptional dimensional stability.

- Easy Mobility: Easy to move when used with our Soap Tray Dollies.

- Dual-Purpose: You can line with our Fizzy Foam to dry your bath bombs as well!

- Easy to Clean: Run through a sanitization wash – up to 180°F.

Description:

- Increase your profit and decrease headaches with our soap drying trays.

- Designed to speed up soap curing by increasing airflow between your bars.

- No more turning bars to get an even cure; reduces potential for damage to intricate bars and products.

- Durable and tough enough to withstand constant and rough handling.

- Non-pourous material is odor and stain resistant.

- Heavy-duty, long-life construction.

- Easy to clean, no sticking, with excellent release characteristics.

- Space Saving and can stack over 6 feet high.

- Made of Food Grade polyethylene.

When placed on one of our Soap Tray Dollies, you have a mobile curing system that can quickly cure 1-2,000 or more bars in only 16” x 32” (41cm x 82cm) of Floor Space!

Drying Trays in Action:

@coastcannaco

@treschik

@creatingbetterbrands

Specifications:

| (A) Overall Length | 30.30″ (770 mm) |

| (B) Overall Width | 16.25″ (413 mm) |

| (C) Overall Height | 4.625″ (118 mm) |

| (D) Inside Length | 29.20″ (741 mm) |

| (E) Inside Width | 15.00″ (381 mm) |

| (F) Side Wall Height | 2.75″ (70 mm) |

| Maximum Drying Height | 4.00″ (102 mm) |

| Weight | 106 ounces (3000 grams) |

Usage Tips:

- The average 3.5 to 4 oz. (100g to 120g) bar size can stack about 100 to a tray (up to about 25 lbs. (11.4 kg)

- We have found that the quickest way to stack and cure your cold process bar soap is to stand them on the long edge.

- Space about 1/8″ (3mm) between the bars and about 1/4″ (6mm) between the rows.

- If the soap bars are under 3/4″ (19mm), you may need to place a row on top of the bars, straddling the rows.

- This method works very well for small samples or guest bars, even down to 3/8″ (9mm) or less. This method locks them together and allows you to move the tray around.

- Speed up curing by placing fans around trays. The slotted design and open sides allow maximum airflow around the product.

- Try our Soap Tray Dolly (solid tray on wheels). It is inexpensive, durable, and works on almost all applications. It also doubles as another tray.

Drying Tray FAQ:

Increasing your airflow between your bars is the best way, and the unique design of our Soap Drying Trays helps with this! They can decrease your drying time by 25% or more.

Once you’ve increased the airflow, you can also:

1. Use Fans: The use of fans in your drying area will speed up the air flow and allow your bars to dry more quickly. Our vented tray design will help facilitate this air flow between your trays.

2. Use Dehumidifier: This will pull water out of the air and make your soap dry faster

3. Use a Water Discount: Discounting your water will speed up your drying process.

You can put your trays on Tray Dollies. We carry several options. For larger operations, it can be useful to stack several stacks on a pallet and move with a pallet jack.

Around 6’ (1.8 meters) is average, but you can go 7’ or 8’ (2 to 2.5 meters) if you want to.

Yes! You can sun-dry or air-dry fruits using our trays. Simply layer the fruits on the trays and leave the trays in the designated drying area. They will not be damaged by the sun or by circulation fans, and are BPA Free!

Nothing! They are synonymous. For instance, there is no difference between bath bomb drying trays and bath bomb curing trays.