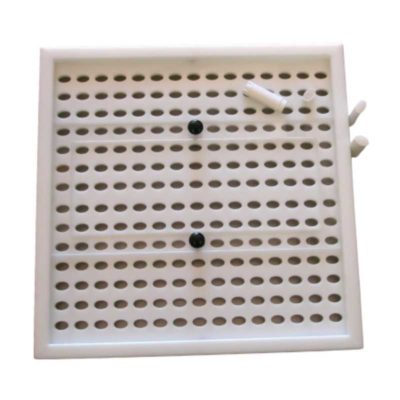

Lip Balm Filling Trays

Benefits:

- Increase Production: Pour hundreds of lip balm tubes in minutes – thousands per day!

- Faster than individual Pours: Flood fill up to 225 lip balm tubes at once instead of pouring individually.

- Save Time & Money: Less labor, less cost per tube. Pour thousands of lip balm tubes a day with one person!

- Increase Profit: Less labor and time means less cost per tube – Equals more profit!

- Custom Designed for You! We can custom-make your lip balm trays to your specifications.

Description:

- The no mess, no spills method of pouring lip balms.

- Made of durable, food-grade High-Density Poly – it will last a lifetime!

- Machined precisely to accept your tubes.

- Custom trays are available for rare tube sizes.

- You will love these lip balm pouring trays and wonder how you ever got by without them.

- Pouring is easy when using our Lip Balm Flood Trays in conjunction with our Wax/M&P Pitchers and All Purpose Melter!

Important Information – All Trays

All Lip Balm Trays require a 6-8 Week Lead Time.

Lip Tolerance:

All Lip Balm Filling Trays, unless otherwise noted, are programmed for a lip tolerance of 0.010″ (0.25mm) and generally average 0.010″ to 0.015″ (0.25-0.38mm) maximum. We normally shoot for a maximum of 0.025″.

Required Tube Samples:

Unless you have purchased a tray within the past year, we request five sample tubes with lids (ten if using cardboard tubes) from you so we may test them with our stock trays to ensure they will fit our specifications. We may add a one-time custom fee if your tubes require a custom tray. Please include your contact information when sending samples.

Please Send Samples To:

Soap Equipment

520 W. Main St.

Hagerstown, IN 47346

Attn: Lip Balm Tray Dept

Please Note: Lip Balm Tray lead times begin once samples arrive.

Lip Balm Trays in Action:

@wildprairiesoap

@lafilledelamer

@kobeesco

Lip Balm Tubes

Why our tubes are better for your business:

|

OTHER SUPPLIERS |

| Save on Filling Trays! Filling Trays are only $250 each when you order our tubes. | No price breaks. |

| No sending samples or waiting for testing is necessary when purchasing our tubes. | 5 samples must be sent to us to ensure the fit is correct for Filling Tray. New samples must be sent every year. |

| No worries about new tube batches not fitting your custom trays. Our tubes fit our trays, period. | New tube batches can have different tolerances or dimensions which can have an impact on the fit in your Filling Tray. |

| Inventory in-stock and ready to ship! | Long lead times, or no ETA at all after purchase! |

Milling vs. Injection Molding

Question:

Why do you mill your Lip Balm Trays instead of injection molding them?

Answer:

We have heard lots of complaints about injection molded trays. Honestly, most of our Lip Balm Tray customers come to us because of their dislike towards injection-molded trays. Tubes fall out, leak, and clean up is a mess every time.

Several things can go wrong with the injection process. For something that requires this level of precision, milling is the only answer.

Question:

I have several small lip balm filling trays (Plastic Tom), which only hold 50 tubes. I don’t like having to trim the lip balm after removing the tubes from the trays. When removing the filled lip balm from your trays, is the lip balm flush with the tube rim, or does it need to be trimmed?

Answer:

There is no trimming needed. Our Lip Balm Trays are machined to a lip tolerance of 0.005″ (0.012mm) and generally average 0.005″ to 0.015″ (0.012-0.038mm). We require an allowance of 0.020″ (0.03mm) which is the thickness of 5 pieces of copy paper from the top of the tray to the lip of the tube.

The lip balm trays you have are injection molded. Tight tolerances cannot be held using this type of method. This is due to the fact that the plastic formula may be off, the injection temperature can be wrong, the injection mold itself is old or maybe not appropriately made in the first place.

We mill our trays from an extruded sheet of HDPE Plastic and measure all four sides with calipers before milling the holes to help ensure we meet our specified tolerances from one side of the tray to the other. This process allows every hole to be precise every time.

Lip Balm Tray Types:

| .15 Ounce Round | .15 Ounce Oval | .25 Ounce Round | .35 / .50 Ounce Oval | .5 Ounce Round | 2.65 Ounce Oval | |

| Tray Capacity | 225 Tubes | 210 Tubes | 225 Tubes | 121 Tubes | 121 Tubes | 45 Tubes |

| Plastic Tube Tray Price | $300 | $300 | $300 | $300 | $300 | $300 |

| Cardboard Tube Tray Price | $425 | $425 | $425 | $425 | $425 | $425 |

Usage Tips:

How To Use Your Lip Balm Filling Tray:

- Insert the tubes into the holes, pushing them in with a slight twist until they rest against the tube shoulder, where the cap would usually stop. The edge of the tube will be flush with the tray’s surface.

- Check that all the tubes are in, or there may be a mysterious leak.

- Set the Lip Balm Tray upright so that the tubes support the tray.

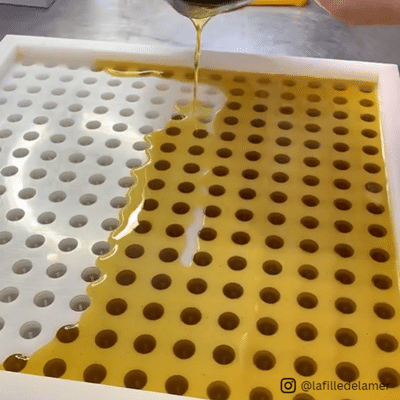

- Pour your lip balm mixture by running each row and filling each tube as you go.

Go back and run the rows quickly, overfilling the tubes. (The material needs a little time to settle. Going back over ensures the tubes are filled all the way) - Leave a thin layer, 1/16″ to 1/8″ (1mm to 3mm) of material over the surface.

- Let the mixture set up and completely solidify depending on your formula and room temperature, anywhere from 15 minutes to 30 minutes.

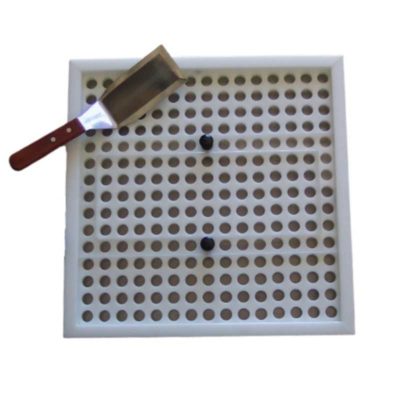

- Scrape off excess with your Tray Scraper. You can save this excess for another pour.

- Pull out the tubes, giving them a little twist when pulling, then capping each tube as you go.

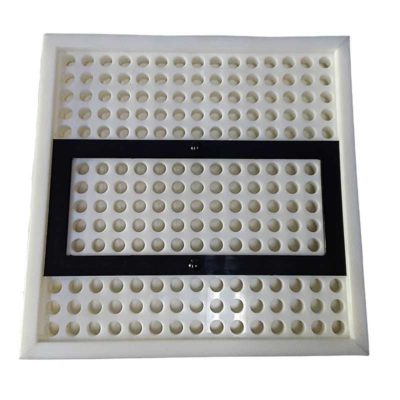

Note: There are more details and instructions on using the divider (optional accessory) for smaller pours in the included instructions.

Lip Balm Tray FAQ:

Air pockets get into your tubes because you’re pouring too quickly.

If you’re having this issue, fill your tubes slowly, running down the rows one by one. Hot balm shrinks as it cools, pouring slowly along the row allows a bit of cooling to take place. When you’re finished with the last row, repeat the process, overfilling the tubes. Always overfill. You can scrape off the excess and use it again.

If you’re still having issues, take a hairdryer or a heat gun and wave over the hole until it melts and levels out. Make sure to keep the heat gun moving, so you don’t risk melting the plastic.

Assuming you have your tubes ready in a box and everything set up and easy to reach, you should be able to place about 25 to 35 tubes per minute. Larger tubes will be closer to the lower end.

A reducer valve will help, as well as having a surface that you can easily slide the tray around as you are filling.

You can use any cleaner on HDPE. We don’t recommend using any abrasive cleaners, as they can mark the surface of the tray.

You can use a heat gun or a hairdryer. Some of our larger manufacturers use heat lamps or heat tunnels with a conveyor.

Most people use a heat gun. It is fast and efficient. We also supply you with a stainless steel knife that leaves a pretty clean surface to begin with.

Any bottle filler, whether single shot, handheld or multiple shot, is going to be slower than flood filling trays. If you want to increase your production above what you’re getting with these trays, you’ll need a full-line conveyor/packaging/filler system. Those will start around $100,000.

Yes, we can, but we don’t recommend it. It’s better to use a lip balm tray divider and split a single tray into multiple sections. Due to the fixturing required, smaller trays are more expensive than the larger ones.

No. Unlike injection molded trays, ours are made from sturdy HDPE plastic and can withstand the temperature of a heat gun.