The silicone seems to work okay for hobbyists and small batch production. We have not found that to be the case ourselves, but we see people using this liner method. Silicone tears and degrades over time, and of course, is expensive. For a large block pour with a Manual Soap Cutter™ Mold, it is just too easy to line a soap mold versus having to handle and wrangle around a 40 lb block of soap to remove the liner.

We have tried about everything out there. We were building professional soap cutters long before anyone else. If silicone were a viable solution for Large Batch SoapMaking, guaranteed, we would have been the first to have perfected it. If you could take a poll of all the SoapMakers out there, you would find that 90% of the companies making large batches and pouring 500 lbs or more of soap per week are using paper liners.

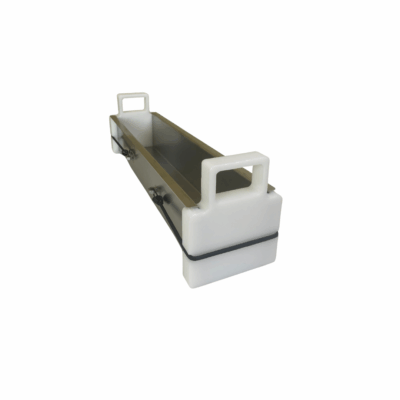

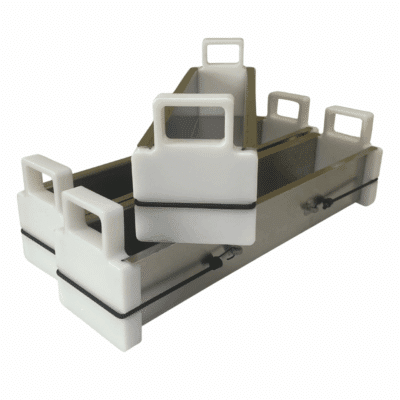

We have designed both of our Pro-Cutters to load easily, either by sliding the block onto a Manual Soap Cutter™ Loaf Table or setting it onto the Air Soap Cutter™ Rolling Table, to cut right from the mold bottom itself. Silicone is too fragile to push around a 40 lb block of soap while sitting on top of it (Manual Soap Cutter™). Having silicone rubber on the bottom of either type of Molds (Air Soap Cutter™ or Manual Soap Cutter™) would prevent the wires from passing through the block of soap into the grooves.

Things like lining, stirring, heating oils, mixing lye, etc., are in the category of being a hassle by the Handcrafted SoapMaker because no one took a step back to find a more efficient method. We happen to be the first to do so. Take, for example, weighing and heating oils; before we started supplying Oil Heaters, people were doing this one batch at a time. It would take hours just heating oils to mix a few batches. Now, all the oils are mixed and heated for several batches all at once. Not only are they heated more efficiently, with less energy but in much less time. The SoapMaker also saves time in measuring both, in and out, of the Oil Heater.

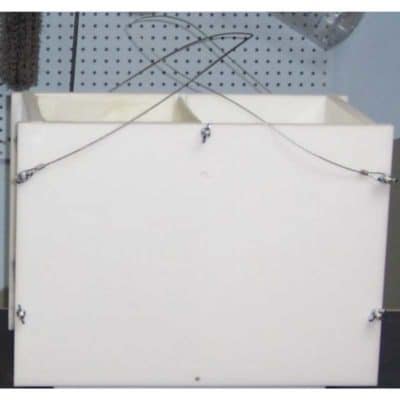

With liners, you would do the same thing, pre-cut lots of liners. It only takes two sizes, one for the bottom the other for the perimeter. The height of the liner is already pre-cut. With a template for the soap mold bottom and a simple mark on the table for the length of the perimeter liner, you can make a hundred sets in a few hours. It takes 30 seconds to line a soap mold if you take the time to get the procedure down pat. You get excellent release both from the soap and from the mold. It makes a very tight corner, adheres tightly to the soap mold, is wrinkle-free, does not outgas, does not need to be washed, and does not matter if you get a little tear in it.