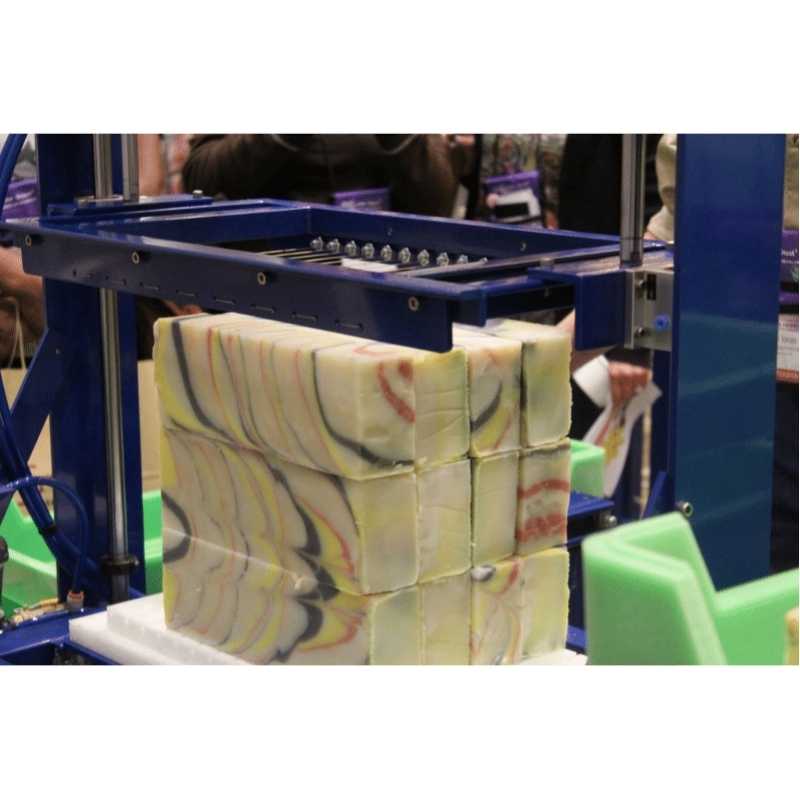

Air Cutter – Soap

-

The most versatile high production Soap Cutter on the market! Designed for the handcrafted SoapMaker.

- A full production custom-made soap cutter designed to your specifications.

- Can produce thousands of perfect bars a day by one person.

- Cuts both loaves and bars with one piece of equipment.

- Note: All Air Cutters and options require a 6-10 week lead time.

From: $8,150.00

Air Cutter Soap Making Components

The Original Air Powered Soap Cutting Machine

Air Cutter Benefits:

- Increase Production: Cut thousands per day easily with one person!

- Cuts 85-130 pound blocks of soap. No more cutting soap in single loaves.

- Effortless Cutting: Pneumatically powered. Save your back and your time!

- Ergonomically Designed: Low cutting table for ease of use and air powered to cut with a press of a button.

- Flexible: Cuts both Loaves and Bars with one piece of equipment.

- Extra Cutting Frames and Tables for different full-size bars or hotel-size bars are available.

- Custom Designed: We custom-make your cutting frames and tables to your specifications.

- Built to Last: Manufactured and designed in the USA. Made to last a lifetime with little to no maintenance.

- Save Time and Increase Profit: Less labor and time means less cost per bar – which equals more profit!

- Small Footprint: The Air Soap Cutter™ is only 32″ (81cm) W x 40″ (102cm) L and is 43” (109cm) H.

Air Cutter Description:

The Air Cutter™ is a pneumatically driven cutter and press that puts a full 600 pounds of power at your fingertips.

- Our ball-bearing gliding table with guide pins glides smoothly out to position your soap block or bath bomb molds automatically.

- Safe to use! The safety valve requires a two-hand operation to release air into cylinders.

- A compact piece of equipment that is tough, durable, easy to use, and easy to clean.

- Air-controlled and powered. The smooth operation is safe, very quiet, and powerful.

- Your Air Cutter™ and Air Cutter Pro Soap Molds™ are made according to your specifications.

- The cutting and pressing frames glide smoothly on linear bearings & high-speed drill-rod guides.

- Soap cutting frames are easily and quickly interchanged.

- De-molding your soap or bath bombs is effortless.

- Optional safety features are available.

- Powered by a small Air Compressor (Not included); see specifications.

Professional Production Math:

Air Cutter System Capacity:

- Typically cuts blocks between 85 lbs -130 lbs (38 – 58kg)

- Size varies to to the size of the bar and the pouring depth

- Maximum block size is 21″ x 12.5″ (53.34cm x 31.75cm)

- Blocks this large typically weigh over 120 lbs (54kg)

- Air cutter molds are single celled.

- Your batch weight is the weight of your soap only. You also need to factor in the weight of your mold for a total weight value.

- Ex: 117 pound batch weight + 40 pound Air Cutter Mold = 157 pound total weight.

- Your batch weight is the weight of your soap only. You also need to factor in the weight of your mold for a total weight value.

- New customers can typically cut 7-13 molds per day with a single person.

- This would be 3,822 – 7,098 bars in a day if you assume 546 bars per mold. Please view production math below for more information on bars cut per day.

- Adding employees and optimizing your cutting/production process can increase your bars cut per day on a much higher level.

- This would be 3,822 – 7,098 bars in a day if you assume 546 bars per mold. Please view production math below for more information on bars cut per day.

- You may also purchase extra cutting frames to produce other bars such as sample bars, hotel sizes, special customer sizes, etc.

Example Bar Sizes with Air Cutter Mold

| Bar Size (L x W x H) | Loaves | Bars / Loaf | Total Bars | Block Size | Batch Weight |

| 3″ x 2″ x 1″ | 42 | 13 | 546 | 21″ L x 12″ L x 13″ H | 117 pounds |

| 4″ x 2.75″ x 1.25″ | 21 | 10 | 210 | 19.25″ L x 12″ x 12.5″ H | 103 pounds |

| 3.5″ x 2.5″ x 1″ | 30 | 13 | 390 | 21″ L x 12.5″ W x 13″ H | 121 pounds |

| 3″ x 3″ x 1″ | 28 | 13 | 364 | 21″ L x 12″ W x 13″ H | 117 pounds |

| 3.25″ x 2.25″ x 1.25″ | 30 | 10 | 300 | 19.5″ L x 11.25″ W x 12.5″ H | 97 pounds |

Air Cutter FAQ:

Loaf vs. Bar Grid

Question:

What is the difference between the Soap Cutter with a loaf grid and the Soap Cutter with a bar grid?

Answer:

They are one and the same! You get two cutting frames with your Air Soap Cutter and Manual Soap Cutter – a Loaf Cutting Frame and a Bar Cutting Frame. The Loaf Grid cuts the face of the bar or width and length. The Bar Grid cuts the thickness.

Logs and Bars

Question:

Does the Air Soap Cutter™ cut in logs and bars or only one type?

Answer:

They both will cut loaves and bars. If you wish, you can also order extra grids for other loaf sizes or bar sizes, such as sample and hotel bar sizes.

Bowed Base Plate

Question:

I recently received your Air Soap Cutter™ and Soap Molds. The base plate for the bar cutter appears to be bowed. It still fits on the pins but it has some rocking to it. Is this a problem?

Answer:

This will not affect your cutting. It is normal for the tables to bow some – no way around it. You will notice that we have scored the other side, to compensate for some of this bowing.

Breaking Wires

Question:

I currently have a block grid cutter (a cheaper variety than the one you sell, made of wood and recycled plastic), and the wires break fairly often, which is time-consuming to replace, sometimes even ruining some of the soap in the process. I’m not sure why, but I need to know the probability of this happening with your unit.

Answer:

I don’t know the gauge or type of wire you use. Our wire is a special grade that only one company in the world makes, as far as I know. We have sold over a thousand cutters over 12 years and seldom need to send replacement wire to anyone.

Sometimes it is not the wire but the wire tying method. We designed our wire bolts to work with the particular wire we use and to pull the wire straight on. We designed the wire bolts to allow tiny adjustments in the tension and to lock firmly in place.

When to Cut Soap

Question:

When should I cut my soap?

Answer:

It is essential when using a wire cutter to cut the soap as soon as possible. Letting the soap cure and harden too long will result in breaking or stretching the wires. Smaller pours require less cure time. Many factors affect curing time, such as environmental surroundings, humidity, air temperature, insulation method, and soap recipe.

For instance: If you make a palm-based formula, you will de-mold sooner than a soy-based formula because it will harden faster.

Record what you see and experience – there is no hard and fast rule. Handcrafted Cold and Hot Processed soap have such a wide range of conditions. Remember, if you wait too long, it can be tough cutting through with your wires.

At first, start checking Manual Cutter™ Molds after about 20 hours. They will usually be ready between 24 and 36 hours, but this can vary greatly.Start checking Air Cutter™ Molds after about 36 hours. Again these are usually ready in about two to three days. The main thing here is to observe and take notes on your first few pours to eliminate mistakes.

You may test your soap by pushing on the top center of the pour. If it is spongy, it is not ready. If it is firm yet still soft, it is ready.

You can also test with a thermometer. Check in the center about mid-way down from the top. It should be ready when the temperature is below 90°F. After a while, you will know by the look and feel of your pour.

Wire Questions:

Question:

I have a few questions about your wires. I have a cutter with guitar tuners, and it keeps losing tension. I am not at all thrilled about this. I have to constantly re-adjust the wire tension. Another problem is turning the knobs; it is tough to do when putting a lot of tension on the wire. What is your method? Is each wire individually controlled with your cutters, and how are they tightened?

Right now, I think I use an 18 gauge wire, and some of my harder bars are very hard to cut. After one or two cuts, I have to redo the tension on the wire

Answer:

The problem with using a heavy wire and guitar tuners is that the tuner cannot handle the heavy wire. The result is that it slips and loses tension.

We machine our tension bolts to hold the wire, so it does not slip. Our system pulls straight through. The wires do not wrap around the bolt. We make tens of thousands of these bolts every year and have found no better method. With that said, we are always looking for ways to improve.

Once it is tensioned a couple of times, it should not need to be adjusted again. There should be little stretch left. We have customers who have gone several years before re-tensioning their wires. We try to get most of the stretch out of the wire before it leaves here.

Each bolt essentially has one wire. If you want individual wires, we can do this for a small charge, but it makes no difference in the performance of our system.

Adjustable Cutters?

Question:

Do you make an adjustable cutter for different bar thicknesses?

Answer:

There would be no adjustable cutter worth its salt. If there were, we would have invented it a long time ago. You would end up having the same problem you are having now – constant problems tensioning wires. The wires can only take so much loosening and tensioning.